About CableDo

Your Trusted USB Cable Manufacturer & Supplier

At CableDo, we are a leading USB cable manufacturer based in China, specializing in custom cable assemblies and OEM solutions for B2B clients across various industries. With over a decade of experience, we have established ourselves as a reliable supplier of high-quality data cables, charging cables, and USB C cables.

As an ISO 9001 certified factory, we ensure that our USB cables and custom assemblies meet the highest quality standards, so you can trust in reliable, consistent products.

Whether you need bulk USB cables, private label USB cables, or custom usb cable solutions, CableDo is your trusted partner for reliable, top-quality products with fast delivery and competitive pricing.

Leading USB Cable Manufacturer & Supplier | Custom Solutions for B2B

Our Products– Custom & Bulk Solutions for Every Need

Whether you need custom USB cables or bulk orders, CableDo offers the best solutions for your business. We are also your go-to source for USB C cable OEM services, supporting high-quality, cost-effective production.

Our Advantages

Why Choose Cabledo as Your USB Cable Manufacturer?

Offer Free Sample

Experience the reliability of our products with free USB cable samples. This allows you to verify the quality and suitability of our custom USB cables before committing to a bulk order, reducing purchase risks and ensuring you make the right choice.

Small MOQ Support

We understand the importance of flexibility. Our low MOQ (minimum order quantity) allows you to order according to actual demand, minimizing inventory waste and reducing risks associated with bulk purchasing. This flexibility helps you launch products faster, keeping you ahead of the competition.

ISO 9001:2015 certified

As an ISO 9001:2015 certified factory, we adhere to the highest international standards in every aspect of our manufacturing process. This certification guarantees that our USB cables and custom assemblies are produced with precision and quality, ensuring long-term reliability and customer satisfaction.

Professional Manufacture

With 9 years of experience in USB cable manufacturing, we have developed extensive industry knowledge and professional capabilities. Whether you need custom USB cable assemblies or bulk orders, we ensure top-quality production and consistent results every time.

Custom Solutions for Your Brands

We offer comprehensive customization options for your USB cables—from color, design, and function to packaging. Our OEM USB cable services and private label solutions ensure your brand remains consistent and stands out in the market with products tailored to your exact requirements.

Reliable Supply Chain for B2B Cable Orders

We take pride in our ability to deliver on time, even during peak seasons. With stable delivery schedules, we help you avoid production delays, minimize extra costs, and ensure timely product launches, keeping your operations running smoothly and maintaining a competitive edge in the market.

Process Flow

USB Cable Manufacture Process

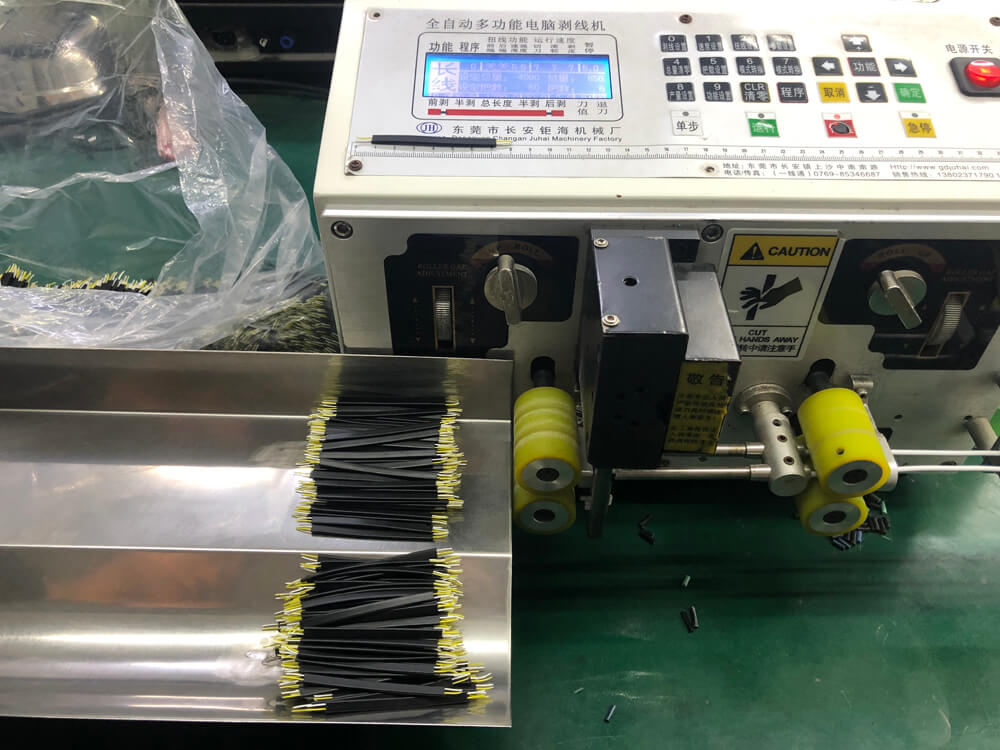

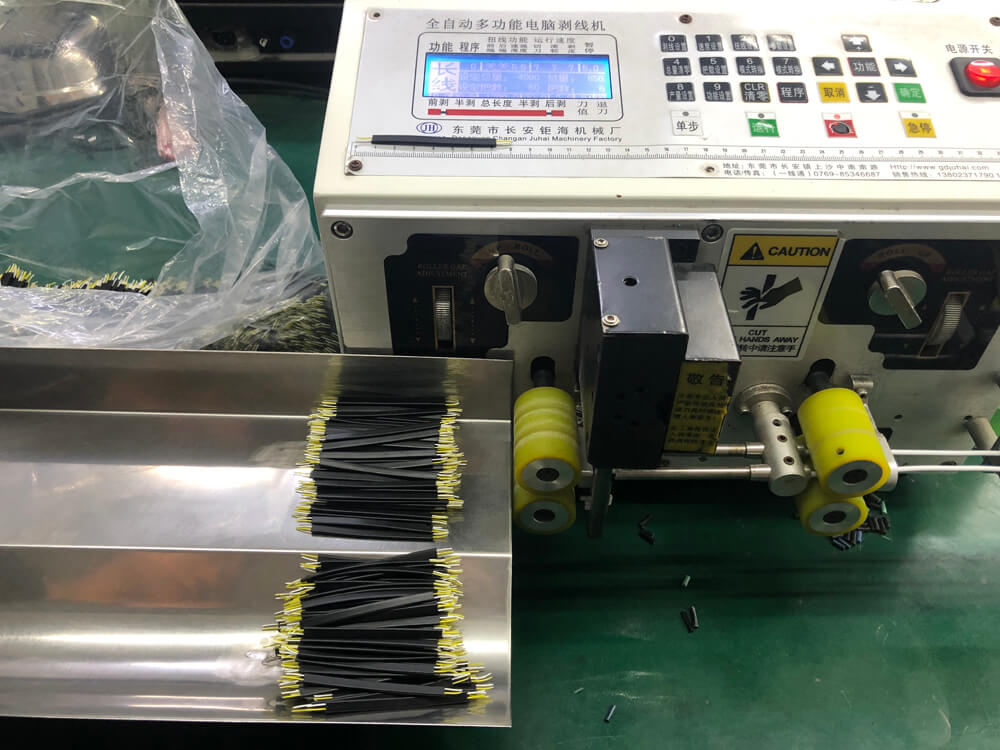

At Cabledo, every USB cable starts with precision and ends with performance. From raw material preparation to final packaging, each stage of our production process is carefully controlled to ensure durability, consistency, and reliability. We take you behind the scenes to show how expert craftsmanship, advanced machinery, and strict quality checks come together to deliver cables you and your customers.

1.Wire Manufacturing

2.Cable Cutting

3.Soldering & assembly

4. Injection Molding

5.Electrical Performance Testing

6.Packaging

We specialize in custom USB cable production and OEM solutions, making us your go-to USB cable vendor.

Quality Control

Quality Control Plan

As a leading USB cable manufacturer, CableDo prioritizes quality at every stage of production. Our ISO-certified factory ensures each cable meets global standards:

Comprehensive Inspection Process

We follow a rigorous, step-by-step quality control process from raw material inspection to final product testing, ensuring every cable meets the highest standards before it reaches our customers.

100% Incoming Material Inspection

Real-time In-Process Monitoring

Quality-First Workflow

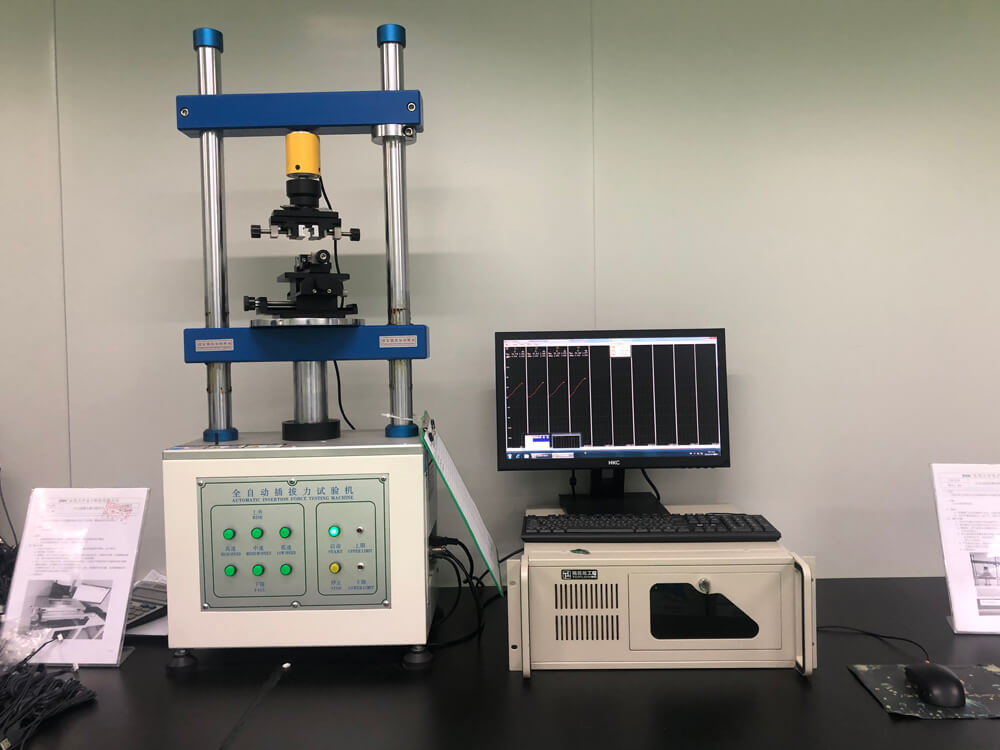

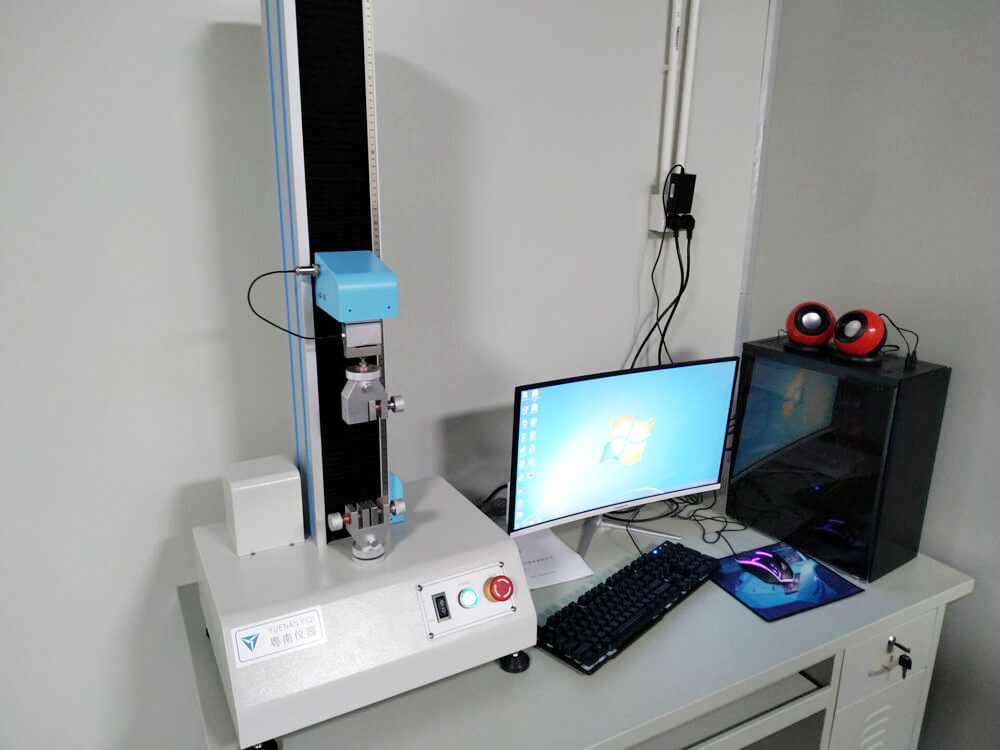

Advanced Testing Equipment

Our commitment to quality goes beyond production—we design every cable to deliver consistent performance, long-term durability, and total reliability you can trust.

Tested for Durability & Performance

Certified Quality Management System

Traceability & Data-Driven Control

Our Quality Control Process

Tired and Tested Reliability

Plug/Unplug Test

Insertion Force Test

Pull Force Test

Salt Spray Test

Bending Test

Certificates

Your Reliable USB Cable Manufacturer

ISO9001

BSCI

UL

EMC

Customize

Custom Your USB Cable

Tailor your USB cables to your exact specifications with our comprehensive customization services, ensuring a perfect match for your brand and needs. Whether you need bulk USB cables for retail kits, custom assemblies for devices, or OEM bundles for new launches, we support usb cable bulk orders with stable quality and on-time delivery.

USB Cable Length

USB Cable Color

USB Cable Style

USB Cable Logo

USB Cable Function

USB Cable Package

Testimonials

what our customers Says

Cabledo has consistently proven to be a reliable supplier for our USB cable needs. Their attention to detail and commitment to quality are evident in every order we receive. Their products have never failed to meet our standards, and their reliability has made them our go-to supplier for USB cables.

-Mike from U.K

We've found Cabledo to be a cost-effective solution for our USB cable requirements. Despite their competitive pricing, they have never compromised on quality. Their ability to provide high-quality cables at a reasonable cost has helped us save on procurement expenses without sacrificing product quality.

-Alice from Switzerland

Our partnership with Cabledo over the past four years has been exceptional. We greatly value their contributions, including streamlined communication, efficient product delivery, and superior quality. Their seamless communication has not only saved us significant costs but also ensured our projects are always on track.

-Laila from

Slovenia